Welcome to CNC-Fertigungstechnik e.K.

Thank you for your interest in our company presentation. With innovative CNC-controlled milling and turning technology we produce precision components, complete assemblies and devices in different materials. For this purpose, we use 13 CNC automatic lathes, 8 CNC machining centers (3 to 11-axis) and various CNC-controlled measuring devices in two workshops at Rennsteig. In addition, we have a wide range of complementary machines and automatic machines.

The "one-stop-shop", from design services to manufacturing, measuring, packaging and shipping, contributes to an extremely cost- and time-efficient processing of orders. We are your partner from component design, through the development of complex systems, to production.

Feel free to contact us with your questions. Trust in our competence. Of course, we strictly adhere to your rules regarding data protection and discretion.

We are looking forward to our first joint project.

Product examples

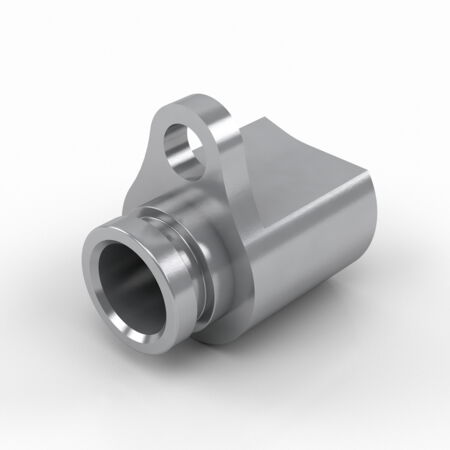

Component for hose assemblies with stainless steel bracket. Such components are produced with CNC milling technology for the automotive industry as a prototype or for pilot series and serves as a connecting element for hose lines. Such parts can be produced in different materials with CNC milling technology or also in combination with CNC turning technology.

Sensor tube or housing for sensor technology. Application for the electrical industry. This or similar components are produced in stainless steel, chrome nickel steel, titanium or other materials. This sensor technology is used in the analysis of liquids in various industries. The penetration of the liquid jet generates physical impulses, which provide corresponding analysis results for the respective liquids.

Valve housing made of stainless steel, manufactured in 5-axis simultaneous machining. Housing is used to accommodate various valve geometries and is used in automatic painting machines.